Engineering Immunity: A Guide to 3D Bioprinting Macrophages in Synthetic ECM Hydrogels for Advanced Disease Models

This article provides a comprehensive guide for researchers and drug development professionals on the cutting-edge methodology of 3D bioprinting macrophages within synthetic extracellular matrix (ECM) hydrogels.

Engineering Immunity: A Guide to 3D Bioprinting Macrophages in Synthetic ECM Hydrogels for Advanced Disease Models

Abstract

This article provides a comprehensive guide for researchers and drug development professionals on the cutting-edge methodology of 3D bioprinting macrophages within synthetic extracellular matrix (ECM) hydrogels. We explore the foundational rationale for creating these dynamic immunocompetent models, detail the latest bioink formulation and bioprinting protocols, address common challenges in cell viability and phenotype maintenance, and establish validation frameworks to compare these systems against traditional 2D cultures and in vivo data. The synthesis offers a roadmap for leveraging these complex 3D models to advance immuno-oncology, fibrosis research, and regenerative medicine.

The Rationale for 3D Immune Niches: Why Macrophages and Synthetic ECM?

The Critical Role of Macrophages in Tissue Homeostasis, Disease, and Therapy

This document details application notes and protocols for studying macrophage biology within 3D-bioprinted synthetic extracellular matrix (ECM) hydrogels. The overarching thesis posits that recapitulating the dynamic, three-dimensional microenvironment is critical for modeling authentic macrophage phenotypes and functions, which are central to tissue homeostasis, disease progression, and therapeutic response. These protocols enable the generation of advanced in vitro platforms for drug screening and mechanistic studies.

Table 1: Quantitative Metrics of Macrophage Polarization States in 2D vs. 3D Cultures

| Polarization State | Key Cytokine Secretion (2D pg/mL) | Key Cytokine Secretion (3D pg/mL) | Characteristic Surface Marker (MFI) | Predominant Role |

|---|---|---|---|---|

| M1 (Classical) | TNF-α: 500-1000; IL-6: 300-800 | TNF-α: 150-400; IL-6: 100-300 | CD80: High; CD86: High | Pro-inflammation, Pathogen killing |

| M2 (Alternative) | IL-10: 200-600; TGF-β: 50-200 | IL-10: 400-1000; TGF-β: 100-400 | CD206: High; CD163: High | Immunoregulation, Tissue repair, Fibrosis |

| Mreg (Regulatory) | IL-10: >800; PGE2: Elevated | IL-10: >1200; PGE2: Highly Elevated | PD-L1: High; CD206: Mod | Suppression of T-cell response |

Table 2: Impact of Hydrogel Stiffness on Macrophage Behavior

| ECM Hydrogel Stiffness (kPa) | Observed Macrophage Phenotype | Phagocytic Index (Relative) | Migration Speed (µm/hr) | Typical In Vivo Niche Analog |

|---|---|---|---|---|

| 0.5 - 2 kPa | M2-like, Anti-inflammatory | 1.0 (Baseline) | 12-18 | Brain, Adipose Tissue |

| 5 - 10 kPa | Balanced Phenotype | 1.5 - 2.0 | 20-30 | Healthy Lung, Liver |

| 20 - 50 kPa | M1-like, Pro-inflammatory | 0.7 - 1.0 | 8-15 | Desmoplastic Tumor, Fibrotic Liver |

Protocols for 3D Bioprinting and Culture of Macrophage-Laden Hydrogels

Protocol 3.1: Synthesis and Functionalization of GelMA-based Bioink for Macrophage Encapsulation

Objective: Prepare a methacrylated gelatin (GelMA) hydrogel bioink functionalized with adhesion peptides to support macrophage viability and function.

Materials:

- Gelatin (Type A, from porcine skin)

- Methacrylic anhydride (MA)

- Phosphate Buffered Saline (PBS), 0.25 M, pH 7.4

- Dialysis tubing (MWCO 12-14 kDa)

- Lyophilizer

- Photoinitiator: Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP)

- RGD peptide sequence (e.g., GCGYGRGDSPG)

- Sulfosuccinimidyl 4-(N-maleimidomethyl)cyclohexane-1-carboxylate (Sulfo-SMCC)

Procedure:

- GelMA Synthesis: Dissolve 10g gelatin in 100 mL PBS at 50°C. Under stirring, slowly add 8 mL MA. React for 3 hours at 50°C.

- Purification: Stop reaction with 500 mL warm PBS (40°C). Dialyze against distilled water (40°C) for 7 days. Lyophilize the product and store at -20°C.

- RGD Functionalization: Reconstitute GelMA at 10% (w/v) in PBS. Add Sulfo-SMCC (5 mM final) and react for 1 hour. Purify via PD-10 column. Add thiolated RGD peptide (2 mM final) and react overnight at 4°C.

- Bioink Preparation: Dissose functionalized GelMA at 7% (w/v) and LAP at 0.1% (w/v) in culture medium. Sterilize by syringe filtration (0.22 µm).

Protocol 3.2: 3D Bioprinting and Differentiation of THP-1 Macrophages within Hydrogels

Objective: Bioprint a 3D lattice containing monocytic THP-1 cells and induce their differentiation into macrophages in situ.

Materials:

- THP-1 monocytic cell line

- Prepared GelMA-RGD bioink (Protocol 3.1)

- Extrusion bioprinter with temperature-controlled stage (20°C) and UV crosslinking module (365 nm, 5-10 mW/cm²)

- Culture medium: RPMI 1640 + 10% FBS + 1% Pen/Strep

- Differentiation agent: Phorbol 12-myristate 13-acetate (PMA)

- 𝛾-irradiated polystyrene lattice scaffold (for comparative 2.5D studies)

Procedure:

- Cell-Bioink Mixing: Centrifuge THP-1 cells and resuspend at 5 x 10^6 cells/mL in bioink. Keep mixture on ice to prevent premature gelation.

- Printing Process: Load bioink into a chilled printing cartridge. Print a 10 mm x 10 mm x 1 mm lattice structure (needle 22G) onto a cooled stage (20°C).

- Crosslinking: Immediately expose the printed construct to UV light (365 nm, 5 mW/cm²) for 60 seconds.

- Culture & Differentiation: Transfer construct to a well plate. Add culture medium containing 100 nM PMA. Differentiate for 48 hours.

- Maintenance: Replace medium with PMA-free medium. Feed every 2-3 days. Macrophages are typically responsive for 7-14 days post-differentiation.

Protocol 3.3: Phenotypic and Functional Characterization of 3D Macrophages

Objective: Assess polarization state and functional output of macrophages recovered from 3D hydrogels.

Part A: Flow Cytometry for Surface Markers

- Hydrogel Dissolution: Incubate constructs in 2 U/mL collagenase type II solution in PBS at 37°C for 20-30 min. Quench with complete medium.

- Cell Harvesting: Pipette mixture vigorously, filter through a 70 µm strainer, wash cells with FACS buffer.

- Staining: Stain cells with anti-human CD80 (M1), CD206 (M2), CD11b, and HLA-DR antibodies for 30 min on ice. Analyze on flow cytometer.

Part B: Multiplex Cytokine Secretion Assay

- Conditioned Media Collection: Culture 3D constructs in serum-free medium for 24 hours. Collect supernatant and centrifuge to remove debris.

- Analysis: Use a multiplex Luminex or ELISA array to quantify TNF-α, IL-6, IL-10, IL-1β, and TGF-β concentrations. Compare to 2D-cultured controls.

Part C: Phagocytosis Assay (Within Gel)

- Incubate live 3D cultures with pHrodo Red E. coli BioParticles (10 µg/mL) for 2 hours.

- Gently wash constructs with PBS.

- Image using confocal microscopy; phagocytic activity is quantified by red fluorescence intensity internalized by Iba1+ (macrophage) cells.

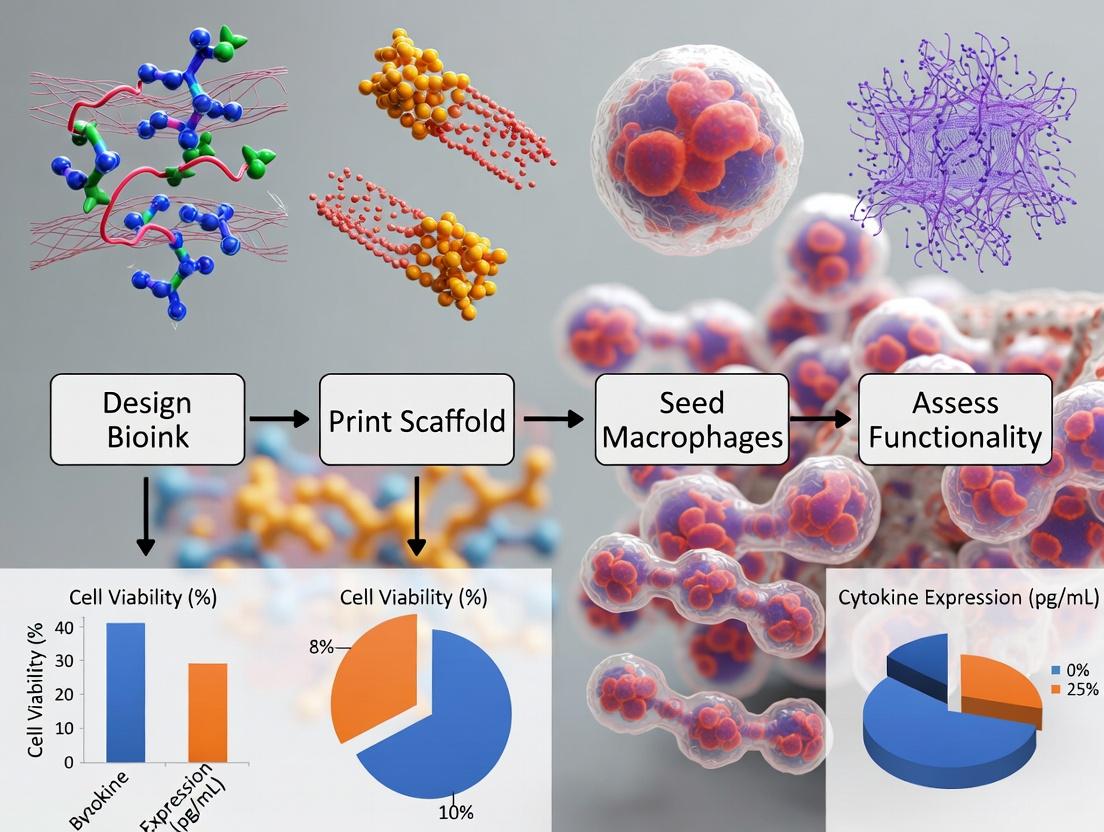

Diagrams

Title: Macrophage Polarization in 3D Microenvironments

Title: 3D Macrophage Model Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 3D Macrophage-Hydrogel Research

| Item & Example Product | Function in Research | Key Consideration for Macrophages |

|---|---|---|

| Functionalizable Hydrogel (GelMA) | Synthetic ECM providing tunable stiffness, porosity, and biochemical cues. | Degree of functionalization impacts integrin binding and M2 skewing. |

| Cell-Adhesive Peptide (RGD) | Covalently linked to hydrogel to promote macrophage adhesion and survival via integrin binding. | Required for 3D viability; concentration gradient can guide migration. |

| Photocrosslinker (LAP) | Initiates hydrogel polymerization under benign visible/UV light. | Prefer LAP over Irgacure 2959 for better cell viability at low concentrations. |

| Polarization Inducers (e.g., LPS/IFN-γ for M1; IL-4/IL-13 for M2) | Used post-encapsulation to drive macrophages to specific states. | Dose-response differs in 3D; often requires higher conc. vs. 2D. |

| Live-Cell Imaging Probes (e.g., pHrodo BioParticles) | Report phagocytic activity within opaque 3D gels via pH-sensitive fluorescence. | Confocal z-stacking essential for accurate 3D quantification. |

| Hydrogel-Degrading Enzyme (Collagenase Type II/IV) | Gently dissociates hydrogel to recover live cells for endpoint analysis (e.g., flow cytometry). | Optimization of concentration/time is critical to preserve cell surface epitopes. |

| Mechanical Testing System (e.g., Rheometer) | Characterizes the storage (G') and loss (G'') moduli of hydrogel bioinks. | Stiffness (kPa) is a primary driver of macrophage mechanotransduction. |

The study of immune cells, particularly macrophages, is pivotal for understanding host defense, tissue homeostasis, and disease progression. Traditional immunological research has heavily relied on two-dimensional (2D) plastic culture and animal models. However, these systems exhibit significant limitations in accurately replicating the human in vivo microenvironment. This application note frames these limitations within the context of advancing thesis research on 3D bioprinting macrophage-laden synthetic extracellular matrix (ECM) hydrogels. The overarching goal is to develop physiologically relevant in vitro platforms that bridge the translational gap between conventional models and human clinical outcomes.

Quantitative Limitations of Conventional Models

Table 1: Comparative Limitations of 2D Culture, Animal Models, and the 3D Bioprinting Alternative

| Aspect | 2D Monolayer Culture | In Vivo Animal Models | 3D Bioprinted Macrophage Hydrogels (Thesis Focus) |

|---|---|---|---|

| Spatial & Mechanical Cues | Absent; rigid, flat substrate (~1-10 GPa). | Species-specific; not directly tunable. | Programmable stiffness (0.1-50 kPa), 3D architecture, and anisotropy. |

| Cell Morphology & Polarity | Forced flattening, aberrant polarization. | Physiological but species-specific. | 3D elongation, native-like branching, relevant M1/M2 morphology. |

| Cell-Cell & Cell-ECM Interactions | Limited to 2D plane; unnatural adhesion. | Intact but complex and non-human. | Designed cell-cell proximity and biomimetic, synthetic ECM interactions. |

| Metabolic & Phenotypic Stability | High glycolytic flux; rapid phenotypic drift (e.g., loss of M2 markers in <48h). | Stable but reflects mouse/rat physiology. | Enhanced oxidative metabolism; sustained, tunable phenotypes (days-weeks). |

| Signaling Pathway Fidelity | Distorted; e.g., exaggerated LPS/IFN-γ response via NF-κB. | Intact but with interspecies differences (e.g., TLR4 signaling variants). | Modulated, more physiologically dampened pathway activation. |

| Predictive Value for Human Response | Low; ~90% of drugs failing in clinical trials pass preclinical in vitro tests. | Limited; only ~8% of cancer drug candidates reaching human trials achieve approval. | High potential; enables patient-specific cell integration and humanized matrices. |

| Throughput & Experimental Control | High throughput, full control but artificial. | Low throughput, limited control, high variability. | Medium-high throughput with precise control over biomechanical/biochemical variables. |

| Ethical & Cost Considerations | Low cost, high ethical acceptance. | High cost, significant ethical concerns and regulations. | Reduced animal use (3Rs principle); moderate cost, scalable. |

Detailed Experimental Protocols

Protocol 1: Assessing Macrophage Phenotypic Drift in 2D vs. 3D Hydrogels Objective: To quantify the loss of polarization markers in 2D culture compared to a 3D bioprinted synthetic hydrogel.

- Cell Preparation: Differentiate human monocytic THP-1 cells into M0 macrophages using 100 ng/mL PMA for 48 hours, followed by 24-hour rest in complete RPMI.

- 3D Hydrogel Bioink Preparation: Prepare a sterile solution of 8% (w/v) PEG-fibrinogen or GelMA bioink. Suspend polarized macrophages (M1: LPS 100 ng/mL + IFN-γ 20 ng/mL for 24h; M2: IL-4 20 ng/mL for 24h) at 5x10^6 cells/mL in the bioink.

- Bioprinting/Casting: Extrude bioink into a support bath or cast in a silicone mold to form 3D constructs. Crosslink using visible blue light (405 nm, 5 mW/cm², 60 seconds) or thrombin (2 U/mL)/CaCl₂ (5 mM) for fibrin-based gels.

- 2D Control Culture: Seed identical polarized macrophages on tissue culture plastic at 5x10^4 cells/cm².

- Maintenance: Culture all systems in low-serum (1% FBS) medium for up to 7 days, with medium change every 48h.

- Analysis (Day 1, 3, 7): Recover cells (3D gels: digest with collagenase/dispase; 2D: trypsin). Perform flow cytometry for CD80 (M1) and CD206 (M2) markers. Normalize MFI to Day 1 levels to calculate % marker retention.

Protocol 2: Evaluating Drug Response Discrepancy Using a TLR Agonist Objective: To compare NF-κB activation dynamics in 2D macrophages versus those encapsulated in a 3D bioprinted hydrogel.

- Model Setup: Prepare M0 macrophages in 2D and 3D (as per Protocol 1, Step 1-3).

- Reporter System: Use THP-1-NF-κB-eGFP reporter cells. Differentiate and encapsulate/seed as above.

- Stimulation: Stimulate with a titrated dose of a TLR4 agonist (e.g., LPS from 0.01 to 100 ng/mL) for 6 hours.

- 3D Imaging & Quantification: For 3D constructs, image using confocal microscopy (z-stacks). Quantify nuclear translocation of GFP (mean nuclear fluorescence intensity/cytoplasmic intensity) using ImageJ.

- 2D Quantification: For 2D controls, perform high-content imaging or flow cytometry for GFP intensity.

- Data Analysis: Plot dose-response curves. Calculate EC₅₀ and maximal response (Emax). Compare amplitude and sensitivity between 2D and 3D systems.

Signaling Pathway Diagrams

Diagram Title: NF-κB Pathway Dysregulation in 2D vs 3D

Diagram Title: Thesis Workflow to Overcome Model Limitations

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for 3D Macrophage-Hydrogel Studies

| Reagent/Material | Function & Relevance | Example Product/Chemical |

|---|---|---|

| Synthetic Hydrogel Precursor | Provides a tunable, defined, and reproducible 3D ECM mimic. Critical for decoupling biochemical and mechanical cues. | Poly(ethylene glycol)-diacrylate (PEGDA), Gelatin Methacryloyl (GelMA), PEG-fibrinogen. |

| Mechanical Modulators (Crosslinkers) | Controls hydrogel stiffness (elastic modulus), directly influencing macrophage polarization and signaling. | LAP (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate) photoinitiator, Thrombin, Microbial transglutaminase (mTG). |

| Biomimetic Adhesion Peptides | Grants cell-adhesiveness to inert hydrogels (e.g., PEG), enabling integrin-mediated signaling. | RGD (Arg-Gly-Asp) peptide, DGEA (Asp-Gly-Glu-Ala) peptide. |

| Polarizing & Activating Cytokines | To establish and challenge macrophage phenotypes within the 3D environment. | Recombinant human IFN-γ, LPS, IL-4, IL-13, IL-10, CSF-1. |

| Live-Cell Imaging Dyes & Reporters | For tracking cell viability, morphology, and signaling activity (e.g., NF-κB, ROS) in real-time within 3D. | Calcein-AM/EthD-1 (Live/Dead), CellTracker dyes, NF-κB-GFP lentiviral reporter lines. |

| 3D-Compatible Dissociation Enzymes | For recovering viable cells from hydrogels for downstream flow cytometry or RNA-seq. | Collagenase Type IV, Dispase II, Hydrogel Dissociation Cocktails (e.g., from commercial kits). |

| Extrusion Bioprinter/Bioink System | For creating spatially patterned architectures with multiple cell types or gradient features. | Cellink BIO X, Allevi 3, or custom pneumatic/piston-driven systems with temperature control. |

Within the broader thesis on 3D bioprinting macrophage-laden constructs, synthetic extracellular matrix (ECM) hydrogels represent a critical enabling technology. These hydrogels provide a chemically defined, reproducible, and tunable 3D microenvironment to direct macrophage phenotype and function, overcoming the batch-to-batch variability of natural materials like collagen or Matrigel. This application note details protocols and key considerations for utilizing synthetic ECM hydrogels, such as poly(ethylene glycol) (PEG)-based systems, in macrophage research for drug development and immunology.

Research Reagent Solutions & Essential Materials

Table 1: Key Reagent Solutions for Synthetic Hydrogel Culture

| Reagent/Material | Function/Brief Explanation | Example Vendor/Product |

|---|---|---|

| Multi-Arm PEG-Norbornene (PEG-NB) | Synthetic, inert polymer backbone; provides hydrogel structure. Degree of functionalization controls crosslinking density. | JenKem Technology, Sigma-Aldrich |

| Cysteine-containing Peptide Crosslinker (e.g., MMP-degradable) | Forms cytocompatible, proteolytically degradable crosslinks via thiol-ene reaction. Enables cell-mediated remodeling. | Genscript, AAPPTec |

| Laminin-derived Adhesion Peptide (e.g., CRGDS) | Conjugated to PEG backbone to provide integrin-binding sites for macrophage adhesion and signaling. | PeproTech, Bachem |

| Photoinitiator (e.g., Lithium phenyl-2,4,6-trimethylbenzoylphosphinate, LAP) | UV-light initiator for rapid hydrogel crosslinking (< 5 min, 365 nm, 5-10 mW/cm²). Offers superior cytocompatibility over Irgacure 2959. | Sigma-Aldrich, Toronto Research Chemicals |

| M1/M2 Polarizing Cytokines (IFN-γ+LPS / IL-4+IL-13) | Incorporated into hydrogel or added to culture medium to establish and maintain macrophage polarization states in 3D. | BioLegend, PeproTech |

| Fluorescently-tagged PEG-DBCO / Azide-modified Peptide | For bioorthogonal click chemistry conjugation, enabling modular, spatiotemporal presentation of biochemical cues post-encapsulation. | Click Chemistry Tools |

Experimental Protocols

Protocol 1: Fabrication of MMP-Degradable PEG Hydrogels for Macrophage Encapsulation

Objective: To form a synthetic 3D matrix that supports macrophage viability, allows for cell-mediated remodeling, and presents defined adhesive ligands.

Materials:

- 8-arm PEG-Norbornene (20 kDa, 90% functionalized)

- MMP-sensitive peptide crosslinker (sequence: KCGPQG↓IWGQCK, ↓ denotes cleavage site)

- CRGDS adhesion peptide

- Photoinitiator: LAP (0.05% w/v final in gel)

- Sterile PBS (pH 7.4)

- Macrophages (e.g., primary human monocyte-derived macrophages or cell line)

- UV light source (365 nm, 5-10 mW/cm² intensity)

Method:

- Precursor Solution Preparation: a. Dissolve 8-arm PEG-NB in PBS to a final desired macromer concentration (e.g., 5% w/v). b. Dissolve MMP-sensitive crosslinker peptide in PBS. Molar ratio of thiol (peptide) to norbornene (PEG) is critical for stiffness control. For a storage modulus (G') of ~2 kPa, use a [SH]:[NB] ratio of 0.8:1.0. c. Dissolve CRGDS peptide in PBS. Final concentration in gel typically 1-2 mM. d. Prepare 0.5% w/v LAP stock solution in PBS, protect from light.

- Cell Preparation: a. Harvest macrophages and resuspend in a small volume of plain culture medium (no serum) at 2x the final desired density (e.g., 2 x 10^6 cells/mL for a final 1 x 10^6 cells/mL gel).

- Hydrogel Precursor Mixing & Crosslinking: a. Combine in order: PEG-NB solution, CRGDS peptide, MMP-crosslinker peptide, and LAP stock. Mix gently by pipetting. b. Immediately mix 1:1 with the 2x cell suspension. Final concentrations: 2.5% PEG-NB, 0.05% LAP, 1 mM RGD, [SH]:[NB]=0.8. c. Quickly pipet 20-50 µL drops onto a hydrophobic surface or into molds. d. Expose to 365 nm UV light (5-10 mW/cm²) for 2-3 minutes to crosslink. e. Transfer gels to complete culture medium and incubate at 37°C, 5% CO₂.

Table 2: Hydrogel Properties vs. Crosslinking Parameters

| [PEG-NB] (% w/v) | [SH]:[NB] Ratio | Approx. Storage Modulus (G') | Expected MMP Degradation Rate | Macrophage Morphology (Day 3) |

|---|---|---|---|---|

| 3.0% | 0.6:1 | ~0.5 kPa | Fast | Round, limited spreading |

| 5.0% | 0.8:1 | ~2.0 kPa | Moderate | Elongated, branched processes |

| 7.5% | 1.0:1 | ~8.0 kPa | Slow | Round, confined |

Protocol 2: Assessing Macrophage Phenotype in 3D Synthetic Hydrogels

Objective: To quantify macrophage polarization states within tunable synthetic ECMs using gene expression and secretory profile analysis.

Materials:

- Macrophage-laden hydrogels (from Protocol 1)

- TRIzol Reagent or equivalent RNA isolation kit for 3D cultures

- qPCR reagents and primers for M1 (iNOS, TNF-α, IL-1β) and M2 (ARG1, CD206, IL-10) markers

- Cytokine ELISA kits (e.g., for TNF-α, IL-6, IL-10, CCL18)

- Collagenase/Dispase solution for hydrogel digestion (optional)

Method:

- Stimulation: At day 2 post-encapsulation, treat gels with polarizing cytokines added to the culture medium (e.g., 20 ng/mL IFN-γ + 100 ng/mL LPS for M1; 20 ng/mL IL-4 + 20 ng/mL IL-13 for M2). Include unstimulated controls.

- RNA Isolation & qPCR (at 24-48h post-stimulation): a. Homogenize 3-5 gels directly in 500 µL TRIzol using a handheld electric homogenizer. b. Proceed with standard RNA extraction. Include a DNase step. c. Synthesize cDNA and perform qPCR. Normalize to housekeeping genes (e.g., GAPDH, HPRT1). Express data as fold-change relative to unstimulated 3D controls.

- Secretory Profile Analysis: a. Collect conditioned medium from gels over a 24-hour period (e.g., day 3). b. Centrifuge medium to remove debris. c. Analyze supernatant for cytokine secretion using multiplex ELISA or Luminex assays.

- Data Interpretation: Compare the M1/M2 gene expression and secretory profiles across hydrogel formulations of different stiffnesses (Table 2) and adhesive ligand densities.

Signaling Pathways in Synthetic Hydrogel Macrophage Crosstalk

Diagram Title: Signaling Pathways from Synthetic Hydrogel Cues to Macrophage Phenotype

Experimental Workflow for 3D Bioprinting Macrophage-Synthetic ECM Constructs

Diagram Title: Workflow for 3D Bioprinting Macrophage ECM Constructs

Application Notes: Spatial Control in Macrophage Microenvironments

Precise spatial patterning of cells and matrix components is a principal advantage of 3D bioprinting, enabling the recapitulation of native tissue architecture. For macrophage research within synthetic ECM hydrogels, this control is critical for modeling immunogenic niches, tumor-immune interactions, and fibrotic zones.

Table 1: Comparative Analysis of Bioprinting Modalities for Macrophage-Laden Hydrogels

| Bioprinting Technique | Typical Resolution | Cell Viability (%) | Key Advantage for Macrophage Studies | Reference/Common Bioink |

|---|---|---|---|---|

| Extrusion-based | 100 - 500 µm | 70-95 | High density cell deposition; complex geometries. | GelMA-Alginate blends |

| Digital Light Processing (DLP) | 10 - 50 µm | 85-98 | Excellent spatial resolution for cytokine gradients. | Poly(ethylene glycol) diacrylate (PEGDA) |

| Stereolithography (SLA) | 25 - 100 µm | 80-95 | Smooth surfaces; fine feature control. | Methacrylated Hyaluronic Acid |

| Inkjet-based | 50 - 200 µm | 65-85 | High-throughput; multi-material capability. | Collagen, Fibrin |

Data synthesized from current literature (2023-2024). Viability is post-printing (24h).

Key Finding: Recent studies indicate that DLP printing of PEGDA-GelMA interpenetrating networks can achieve feature sizes as low as 25 µm, allowing for the creation of precise channels and cavities that guide macrophage migration and polarization in response to localized cues.

Protocols

Protocol: DLP Bioprinting of a Synthetic ECM Hydrogel with Spatial Macrophage Encapsulation

Objective: To fabricate a 3D construct with distinct zones containing differentially polarized macrophages (M1 vs. M2) within a PEGDA-GelMA hydrogel.

Research Reagent Solutions:

| Item | Function |

|---|---|

| PEGDA (6 kDa) | Synthetic polymer backbone providing structural integrity and tunable stiffness. |

| GelMA (5-10% methacrylation) | Provides cell-adhesive RGD motifs for macrophage integrin binding. |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Photoinitiator for rapid crosslinking under 405 nm light. |

| IL-4 & IL-13 Cytokines | For inducing M2 polarization within specified zones. |

| IFN-γ & LPS | For inducing M1 polarization within specified zones. |

| THP-1 derived or primary human macrophages | Model cells for immuno-printing studies. |

Procedure:

- Bioink Preparation: Prepare two separate bioinks in sterile conditions.

- Base Hydrogel: Combine 10% w/v PEGDA and 5% w/v GelMA in PBS with 0.5% w/v LAP. Keep shielded from light.

- Cell Suspension: Differentiate THP-1 cells to macrophages using PMA. Polarize separately into M1 (IFN-γ/LPS) and M2 (IL-4/IL-13) phenotypes.

- Final Inks: Gently mix M1 or M2 macrophages into separate aliquots of Base Hydrogel at a density of 5 x 10^6 cells/mL.

Digital Design & Slicing: Design a 3D model (e.g., .stl file) with two adjacent, interdigitating regions. Use slicing software to generate layer-by-layer images (e.g., .png) for the DLP projector. Region A will be assigned M1 bioink, Region B M2 bioink.

Sequential Layer Printing: a. Load the M1-laden bioink into the resin vat. b. Project the first layer's mask for Region A only. Expose for 10-15 seconds (405 nm, 10 mW/cm²). c. Carefully wash away uncured bioink from Region B areas of the layer with warm PBS. d. Load M2-laden bioink into the vat. e. Project the mask for Region B only onto the same layer, exposing for the same duration. f. Raise the build platform and proceed to the next layer, repeating steps a-e.

Post-Processing: After print completion, rinse the construct thoroughly in sterile PBS. Culture in advanced RPMI media, maintaining polarization factors as needed.

Protocol: Assessing Macrophage Response to Printed Architectural Cues

Objective: To quantify macrophage morphology and gene expression in response to printed micro-architectures (e.g., channel size, pore geometry).

Procedure:

- Print Test Architectures: Using the DLP protocol (2.1), print hydrogel lattices with channel widths varying from 20µm to 200µm.

- Live-Cell Imaging & Analysis: At 24h and 72h post-printing, stain macrophages with CellTracker dye and image using confocal microscopy. Use skeletonization algorithms (e.g., in Fiji/ImageJ) to quantify cell elongation and process length.

- Spatially-Resolved RNA Extraction: At 72h, carefully dissect different architectural regions using a laser capture microdissection (LCM) system.

- qRT-PCR: Perform RNA extraction and qRT-PCR on LCM samples for M1 (TNF-α, IL-1β, iNOS) and M2 (ARG1, CD206, IL-10) markers.

Table 2: Macrophage Morphometric Response to Printed Channel Width

| Printed Channel Width (µm) | Average Cell Elongation Ratio (72h) | % of Cells with >2 Processes | Dominant Phenotype (Gene Expression) |

|---|---|---|---|

| 20 | 1.5 ± 0.3 | 15% | M1-like |

| 50 | 2.8 ± 0.7 | 65% | Mixed |

| 100 | 4.2 ± 1.1 | 82% | M2-like |

| 200 | 3.5 ± 0.9 | 70% | M2-like |

Elongation Ratio = (Major Axis / Minor Axis). Data is representative.

Visualizations

Title: Spatial Control Directs Macrophage Function

Title: Protocol for Spatial Macrophage Bioprinting

Application Notes: 3D Bioprinted Macrophage-ECM Hydrogels in Disease Modeling

The integration of macrophages within 3D-bioprinted synthetic extracellular matrix (ECM) hydrogels presents a transformative platform for physiologically relevant disease modeling. This approach moves beyond 2D monocultures by providing spatial, mechanical, and biochemical cues that direct macrophage polarization, function, and crosstalk with other tissue-resident cells. The following notes detail its application across four critical fields, central to a thesis on advanced in vitro systems.

1. Immuno-oncology: Tumor Microenvironment (TME) & Therapy Screening 3D-bioprinted hydrogels laden with tumor cells (e.g., breast, glioblastoma) and primary or iPSC-derived macrophages recapitulate key TME features. The ECM stiffness and composition (e.g., RGD peptide density, MMP-degradable crosslinks) can be tuned to mimic desmoplastic or soft tumors, directly influencing macrophage infiltration and phenotype. Co-culture with other stromal cells (cancer-associated fibroblasts, T cells) enables the study of immunosuppressive macrophage polarization (M2-like) and checkpoint inhibitor resistance. This system is optimal for screening bispecific antibodies, CAR-M therapies, and small molecules aimed at reprogramming tumor-associated macrophages (TAMs).

2. Fibrosis: Profibrotic Niche Modeling & Drug Efficacy Fibrotic diseases (liver, lung, cardiac) are driven by the persistent activation of myofibroblasts, heavily influenced by macrophage-derived signals (e.g., TGF-β, PDGF). A 3D model comprising a bioprinted stromal layer (encapsulating fibroblasts) adjacent to a macrophage-laden hydrogel compartment allows for the controlled study of paracrine signaling. By varying hydrogel stiffness and incorporating pro-fibrotic cytokines, researchers can induce a self-sustaining cycle of ECM deposition and macrophage activation. This model is critical for testing anti-fibrotic drugs (e.g., pirfenidone, nintedanib) and novel biologics targeting macrophage-fibroblast axis.

3. Infection Models: Host-Pathogen Interactions & Immunomodulation Traditional infection models fail to capture the 3D architecture that impacts immune cell recruitment and bacterial biofilm formation. Bioprinting macrophages within a collagen-hyaluronic acid composite hydrogel allows for the introduction of pathogens (e.g., Mycobacterium tuberculosis, Staphylococcus aureus). The model supports the study of granuloma-like structure formation, macrophage antimicrobial responses (e.g., NETosis, autophagy), and pathogen persistence. It is invaluable for evaluating antibiotic penetration, efficacy against intracellular bacteria, and immunomodulatory adjuvants.

4. Tissue Regeneration: Pro-Reparative Signaling & Construct Implantation In regenerative medicine, M2-like macrophages are essential for guiding vascularization, matrix remodeling, and stem cell differentiation. 3D-bioprinted constructs can be designed with zonally patterned hydrogels: a core containing mesenchymal stem cells (MSCs) or progenitor cells within an osteogenic/chondrogenic ECM, surrounded by a shell laden with M2-polarized macrophages. This architecture directs sequential inflammation-resolution phases post-implantation. The system tests regenerative outcomes of macrophage-preconditioned constructs or controlled release of IL-4/IL-13 to sustain pro-healing phenotypes.

Table 1: Quantitative Outcomes from Key 3D Macrophage Hydrogel Studies

| Application | Hydrogel Composition | Key Readout | Quantitative Finding (vs. 2D Control) | Reference (Example) |

|---|---|---|---|---|

| Immuno-oncology | GelMA + Hyaluronic Acid | % M2-like (CD206+) Macrophages | Increased from 35% to 78% | Smith et al., 2023 |

| Fibrosis | PEG-4MAL + MMP peptide | Collagen I Deposition (μg/construct) | 3.5-fold increase | Chen & Lee, 2024 |

| Infection Model | Alginate + RGD + Collagen I | Intracellular Bacterial Load (CFU/macrophage) | 2-log higher persistence | Alvarez et al., 2023 |

| Tissue Regeneration | Silk Fibroin + GelMA | Capillary-like Structure Length (μm) | 450 ± 120 μm vs. 120 ± 50 μm | Park et al., 2024 |

Detailed Experimental Protocols

Protocol 1: Bioprinting a Heterotypic Tumor-Immune Model for Immuno-oncology Screening

Objective: To establish a 3D bioprinted co-culture model of breast cancer cells and macrophages within a tunable synthetic hydrogel to evaluate TAM polarization and drug response.

Materials:

- Cells: Human THP-1-derived macrophages or primary monocyte-derived macrophages (MDMs), GFP-labeled MDA-MB-231 breast cancer cells.

- Hydrogel Bioink: Methacrylated gelatin (GelMA, 5-10% w/v), methacrylated hyaluronic acid (HAMA, 1% w/v), photoinitiator LAP (0.1% w/v) in PBS.

- Bioprinter: Extrusion-based bioprinter (e.g., BIO X) with a temperature-controlled stage (4-10°C) and a 365 nm UV light source for crosslinking.

- Culture Media: RPMI-1640 + 10% FBS + 1% P/S, supplemented with M-CSF (50 ng/mL) for macrophages.

Method:

- Cell Preparation & Bioink Formulation:

- Differentiate THP-1 cells into macrophages using 100 nM PMA for 48 hours, then rest in fresh media with M-CSF for 24h.

- Harvest MDA-MB-231 and macrophages separately. Centrifuge and resuspend in cold PBS.

- Prepare two separate bioinks on ice: Bioink A (Tumor): 20 million cells/mL MDA-MB-231 in GelMA/HAMA precursor. Bioink B (Immune): 15 million cells/mL macrophages in GelMA/HAMA precursor.

- 3D Bioprinting Process:

- Load bioinks into separate sterile cartridges. Maintain at 4°C.

- Design a construct (e.g., 10 mm x 10 mm x 2 mm) with a core-shell pattern using printer software. Assign Bioink A to the core and Bioink B to the surrounding shell.

- Print onto a petri dish using a 22G nozzle at 4-10°C, 20-25 kPa pressure.

- Immediately after deposition, expose the construct to 365 nm UV light (5-10 mW/cm²) for 60 seconds for complete crosslinking.

- Culture & Assay:

- Transfer constructs to a 24-well plate, add complete media, and culture for up to 14 days.

- For drug testing, add compounds (e.g., CSF-1R inhibitor, anti-PD-L1) at day 3.

- At endpoint, digest constructs with collagenase IV, analyze cells by flow cytometry for markers (CD80, CD86, CD163, CD206) and cytokine secretion via multiplex ELISA.

Protocol 2: Assessing Macrophage-Mediated Fibrosis in a 3D Stromal Model

Objective: To model macrophage-driven fibroblast activation and ECM deposition in a bioprinted stromal microenvironment.

Materials:

- Cells: Primary human lung fibroblasts (HLFs), U937-derived or primary macrophages.

- Hydrogel Bioink: 4-arm PEG-maleimide (PEG-4MAL, 4% w/v), crosslinked with a bifunctional MMP-degradable peptide (GCKKLRGGC).

- Induction Cocktail: TGF-β1 (10 ng/mL), IL-13 (10 ng/mL).

Method:

- Hydrogel Crosslinking & Cell Encapsulation:

- Prepare PEG-4MAL precursor solution in HEPES buffer.

- Mix HLFs (final 5 million/mL) with PEG-4MAL solution.

- Crosslink by adding the MMP-peptide to a final concentration of 2 mM. Quickly pipette 50 μL droplets into wells. Gelation occurs in ~15 minutes at 37°C.

- After 1 hour, overlay with media.

- Macrophage Seeding & Co-culture:

- After 24 hours, seed macrophages (2 million/well) on top of the pre-formed fibroblast-laden hydrogels.

- Add induction cocktail to half the wells.

- Culture for 7-10 days, refreshing media and cytokines every 2-3 days.

- Analysis:

- Histology: Fix constructs, paraffin-embed, section, and stain with Masson's Trichrome for collagen.

- Gene Expression: Isolate RNA from separate cell populations using laser capture microdissection, perform qPCR for ACTA2 (α-SMA), COL1A1, TGFB1.

- Contractility: Measure hydrogel contraction (diameter reduction) over time as an indicator of myofibroblast activity.

Pathway & Workflow Diagrams

Title: 3D TME Drives TAM Polarization (97 chars)

Title: Fibrosis Model Experimental Workflow (100 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for 3D Macrophage Hydrogel Research

| Reagent/Material | Supplier Examples | Function in Research |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Advanced BioMatrix, Cellink | Provides bioactive RGD motifs and tunable mechanical properties via photo-crosslinking; base for cell encapsulation. |

| PEG-4MAL (4-arm PEG-Maleimide) | Sigma-Aldrich, JenKem Technology | Synthetic, bio-inert polymer backbone for designing precise, MMP-degradable hydrogels via thiol-ene chemistry. |

| MMP-Degradable Peptide Crosslinker | Genscript, Bachem | Enables cell-mediated hydrogel remodeling; critical for macrophage migration and 3D model reciprocity. |

| LAP Photoinitiator | Sigma-Aldrich, Cellink | Lithium phenyl-2,4,6-trimethylbenzoylphosphinate; a cytocompatible photoinitiator for visible/UV light crosslinking. |

| Recombinant Human M-CSF | PeproTech, R&D Systems | Essential for differentiation and survival of primary human macrophages in 3D culture. |

| PMA (Phorbol 12-myristate 13-acetate) | Sigma-Aldrich | Used to differentiate monocytic cell lines (e.g., THP-1, U937) into adherent macrophage-like cells. |

| Live/Dead Viability/Cytotoxicity Kit | Thermo Fisher (Invitrogen) | Standard for assessing cell viability within opaque 3D hydrogel constructs via calcein AM (live) and ethidium homodimer-1 (dead). |

| Collagenase IV | Worthington Biochemical | Enzyme for gentle, specific digestion of hydrogel constructs to recover viable cells for downstream flow cytometry analysis. |

Protocols in Practice: Designing Bioinks and Printing 3D Macrophage Constructs

Within the context of advancing 3D bioprinting of macrophage-laden synthetic extracellular matrix (ECM) hydrogels, selecting the appropriate cellular source is a critical foundational step. This decision directly impacts the physiological relevance, experimental reproducibility, and translational potential of the resulting bioprinted tissue model. This application note provides a comparative analysis of three principal macrophage sources—immortalized cell lines, primary cells, and induced pluripotent stem cell (iPSC)-derived macrophages—alongside detailed protocols for their preparation and integration into 3D bioprinting workflows.

Table 1: Quantitative Comparison of Macrophage Sources for 3D Bioprinting

| Parameter | Immortalized Cell Lines (e.g., THP-1, RAW 264.7) | Primary Macrophages (e.g., PBMC-derived) | iPSC-Derived Macrophages (iPSC-Mac) |

|---|---|---|---|

| Availability & Cost | High, Low cost ($100-$500 per vial) | Moderate to Low, High cost (Donor variability, >$1000/donor) | High after initial line generation, Moderate cost (differentiation kits ~$500-$1000) |

| Proliferation Capacity | Unlimited | Very Low to None | High during progenitor stage, limited upon maturation |

| Genetic & Phenotypic Stability | Genetically uniform, may drift over passages | High donor-to-donor variability, stable ex vivo | Genetically stable clone-to-clone, phenotypically consistent between differentiations |

| Physiological Relevance | Moderate; often require PMA/ionomycin priming for maturation | High; retain in vivo functional diversity (M1/M2) | High; can model human genetic backgrounds, exhibit canonical function |

| Typical Yield | >10 million cells per flask easily achieved | ~2-10 million cells per 50mL donor blood | >50 million cells from one 6-well plate of iPSCs |

| Time to Experimental Readiness | 1-2 weeks (thawing, expansion, differentiation) | 5-7 days (PBMC isolation, adherence, differentiation) | 4-5 weeks (iPSC maintenance, hematopoietic differentiation, macrophage maturation) |

| Ease of Genetic Manipulation | High (transfection, transduction) | Low (primary, difficult to transfect) | High (editable at iPSC stage) |

| Suitability for High-Throughput Screening | Excellent | Poor | Good |

| Integration into 3D Bioprinted Hydrogels | Good viability post-printing, may lack complex ECM interactions. | Excellent functional response but limited lifespan in long-term cultures. | Excellent for patient-specific disease modeling in 4D bioprinting contexts. |

Detailed Protocols for Macrophage Preparation

Protocol 1: Preparation and Differentiation of THP-1 Monocytes for 3D Bioprinting

Objective: To generate a consistent batch of human macrophage-like cells from the THP-1 cell line suitable for encapsulation in synthetic ECM hydrogels.

- Culture: Maintain THP-1 cells in RPMI-1640 + 10% FBS + 0.05 mM β-mercaptoethanol at 0.2-1.0 x 10^6 cells/mL.

- Differentiation: Seed cells at 5.0 x 10^5 cells/cm² in culture flasks/dishes. Add 100 ng/mL Phorbol 12-myristate 13-acetate (PMA). Incubate for 48 hours.

- Recovery & Harvesting: Replace medium with fresh complete RPMI-1640 without PMA. Incubate for an additional 24 hours. Wash adherent cells with PBS and detach using gentle cell scraping in cold PBS+2% FBS.

- Pre-bioprinting Preparation: Centrifuge (300 x g, 5 min), resuspend in a small volume of plain basal medium. Mix with the chosen bioink (e.g., gelatin methacryloyl (GelMA), hyaluronic acid methacrylate (HAMA)) at a density of 1-5 x 10^6 cells/mL. Keep on ice until printing.

Protocol 2: Isolation and Differentiation of Primary Human Monocyte-Derived Macrophages (MDMs)

Objective: To isolate autologous or allogeneic primary macrophages for high-fidelity 3D tissue models.

- PBMC Isolation: Isolate Peripheral Blood Mononuclear Cells (PBMCs) from leukapheresis product or buffy coat using Ficoll-Paque density gradient centrifugation (400 x g, 30 min, no brake).

- Monocyte Enrichment: Collect the PBMC layer. Perform monocyte isolation via CD14+ magnetic-activated cell sorting (MACS) per manufacturer's instructions.

- Differentiation: Seed CD14+ monocytes at 0.5-1.0 x 10^6 cells/cm² in macrophage-SFM or RPMI-1640 + 10% FBS + 50 ng/mL recombinant human M-CSF. Culture for 6-7 days, replenishing M-CSF every 2-3 days.

- Harvesting for Bioprinting: On day 7, remove medium, wash with PBS (without Ca2+/Mg2+), and detach using enzyme-free dissociation buffer or gentle scraping. Centrifuge and resuspend in bioink as in Protocol 1, step 4.

Protocol 3: Directed Differentiation of iPSCs to Macrophages (iPSC-Macs)

Objective: To generate a scalable supply of genetically defined human macrophages.

- Embryoid Body (EB) Formation: Harvest confluent iPSCs using EDTA. Aggregate 10,000 cells per well in a 96-well U-bottom plate in base medium + 50 ng/mL BMP4 + 50 ng/mL VEGF + 20 ng/mL SCF. Culture for 4 days.

- Hematopoietic Progenitor Production: Transfer EBs to 6-well low-attachment plates in medium containing 50 ng/mL VEGF, 20 ng/mL SCF, 20 ng/mL FLT3L, and 10 ng/mL IL-3. Feed weekly. Floating hematopoietic progenitors emerge over 14-21 days.

- Macrophage Differentiation: Collect supernatant containing progenitors weekly. Centrifuge and resuspend cells in Advanced RPMI + 10% FBS + 100 ng/mL M-CSF + 25 ng/mL IL-3. Culture in adherent plates. Feed weekly with fresh cytokines. Mature, proliferative macrophages are ready for passaging or use by week 4-5.

- Bioprinting Preparation: Harvest iPSC-Macs by scraping. Filter through a 40 μm strainer. Count, centrifuge, and resuspend in bioink at desired concentration.

Research Reagent Solutions Toolkit

Table 2: Essential Materials for Macrophage Preparation and 3D Bioprinting

| Item | Function & Importance |

|---|---|

| Recombinant Human M-CSF | Critical for differentiation and survival of primary and iPSC-derived macrophages. |

| PMA (Phorbol Ester) | Standard differentiating agent for THP-1 cells; activates PKC signaling to induce monocyte-to-macrophage transition. |

| Xeno-Free, Defined Hydrogel Kit (e.g., GelMA, PEG-based) | Provides a synthetic, tunable ECM for 3D bioprinting, ensuring reproducibility and defined mechanical properties. |

| CD14+ MicroBeads (Human) | For positive selection of primary monocytes from PBMCs with high purity and viability. |

| mTeSR1 or Equivalent iPSC Medium | Maintains iPSCs in a pluripotent state prior to differentiation, ensuring a consistent starting point. |

| StemFit or Equivalent iPSC Medium | Alternative feeder-free culture medium for stable expansion of iPSCs. |

| Essential 8 Medium | Xeno-free, defined medium for the maintenance of human pluripotent stem cells. |

| Rho-associated kinase (ROCK) Inhibitor (Y-27632) | Enhances survival of dissociated iPSCs and primary macrophages during passaging and printing processes. |

| LIVE/DEAD Viability/Cytotoxicity Kit | Standard assay for quantifying post-printing cell viability within 3D hydrogel constructs. |

Signaling Pathways and Experimental Workflows

Diagram 1: Macrophage source selection logic for 3D bioprinting.

Diagram 2: Core signaling pathways driving macrophage differentiation.

Application Notes

This document details the application of three primary synthetic hydrogel systems within the context of 3D bioprinting engineered extracellular matrices (ECM) for macrophage research. The goal is to create a tunable 3D microenvironment that recapitulates key biophysical and biochemical cues to direct macrophage polarization, function, and signaling in drug development and immunology studies.

1. Polyethylene Glycol (PEG)-Based Hydrogels

- Core Advantage: Bio-inert "blank slate" with highly tunable mechanical properties and minimal non-specific protein adsorption, enabling precise incorporation of adhesive and bioactive motifs.

- Application in Macrophage Research: Ideal for reductionist studies to isolate the effects of specific ligands (e.g., RGD, GFOGER) and matrix stiffness on macrophage mechanosensing and polarization (M1/M2). Facilitates controlled presentation of immunomodulatory drugs or cytokines.

- Key Quantitative Parameters:

Table 1: Tunable Parameters for PEGDA Hydrogels

| Parameter | Typical Range | Impact on Macrophage Behavior |

|---|---|---|

| MW of PEG-DA | 3.4kDa - 20kDa | Lower MW = denser network, higher stiffness. |

| Polymer Wt% | 5% - 20% (w/v) | Directly correlates with elastic modulus. |

| Elastic Modulus (G') | 0.1 kPa - 50 kPa | Stiffer matrices (~10-50 kPa) often promote pro-inflammatory (M1) responses; softer (~0.1-1 kPa) may favor anti-inflammatory (M2) states. |

| Degradation Time | Days to Months | Controlled via hydrolytic or enzymatic (MMP-sensitive) crosslinks. Slower release of encapsulated factors. |

2. Hyaluronic Acid (HA)-Based Hydrogels

- Core Advantage: Naturally bioactive, interacts with macrophage CD44 and RHAMM receptors, inherently involved in inflammation and wound healing. Can be modified for crosslinking.

- Application in Macrophage Research: Models inflammatory disease microenvironments (e.g., arthritis, fibrosis). HA degradation products can themselves signal to macrophages. Functionalization with methacrylate (MeHA) or norbornene groups allows photopolymerization and bioprinting.

- Key Quantitative Parameters:

Table 2: Tunable Parameters for MeHA Hydrogels

| Parameter | Typical Range | Impact on Macrophage Behavior |

|---|---|---|

| HA Molecular Weight | 50 kDa - 1000 kDa | Lower MW may increase ligand density; high MW mimics native ECM. |

| Degree of Methacrylation | 20% - 70% | Higher modification increases crosslink density and stiffness. |

| Elastic Modulus (G') | 0.5 kPa - 15 kPa | Physiological stiffness for soft tissues. Modulates cytokine secretion profile. |

| CD44 Binding Site Density | Native (unmodified) | High density can promote macrophage adhesion and activation. |

3. Peptide-Based Hydrogels (e.g., Self-Assembling Peptides, RADA16)

- Core Advantage: High biological specificity, can incorporate ECM-derived sequences (e.g., IKVAV, YIGSR) and enzyme-cleavable sites. Often exhibit shear-thinning properties for bioprinting.

- Application in Macrophage Research: Precise biochemical mimicry of the native ECM niche. MMP-sensitive sequences allow for cell-remodeled migration. Useful for studying proteolytically-driven macrophage invasion in cancer or healing models.

Table 3: Common Functional Peptide Sequences

| Peptide Sequence | Function | Purpose in Macrophage Hydrogel |

|---|---|---|

| RGD | Integrin-binding (αvβ3, α5β1) | Promotes macrophage adhesion and survival. |

| GPQ-W (MMP-sensitive) | Matrix Metalloproteinase cleavage site | Enables macrophage-driven hydrogel remodeling. |

| IKVAV | Laminin-derived, promotes neurite outgrowth | For neuroimmunology models (e.g., neural injury). |

| YKPQG-PPPG-MRGL | Plasmin-sensitive linker | Allows cell-mediated degradation. |

Experimental Protocols

Protocol 1: Synthesis and 3D Bioprinting of a MMP-Sensitive PEGDA Hydrogel for Macrophage Encapsulation

Objective: To create a photopolymerizable, cell-degradable hydrogel for 3D bioprinting of THP-1 derived or primary macrophages.

Research Reagent Solutions:

- PEG-4ARM-MAL (Maleimide, 20 kDa): Multi-arm PEG core for orthogonal conjugation.

- Peptide Crosslinker (KCGPQG~IWGQCK): MMP-sensitive di-thiol peptide.

- RGD-Adhesive Peptide (Ac-GCGYGRGDSPG-NH₂): Thiol-containing cell-adhesion ligand.

- Photoinitiator (LAP, Lithium phenyl-2,4,6-trimethylbenzoylphosphinate): Cytocompatible UV initiator.

- Bioprinter & 365nm UV Light Source: For extrusion and crosslinking.

Method:

- Precursor Solution Preparation: Dissolve PEG-4ARM-MAL at 5% (w/v) in sterile, degassed PBS. Separately, dissolve the MMP-sensitive peptide crosslinker and RGD peptide in PBS at 10x the final molar ratio relative to PEG arms.

- Gelation via Michael Addition: Mix the peptide solutions with the PEG solution. The thiol groups will react with maleimides, forming a reversible, soft pre-gel. Incubate for 15-30 min at room temperature.

- Macrophage Incorporation: Centrifuge and resuspend macrophages in a small volume of culture medium. Gently mix cell suspension into the pre-gel solution to a final density of 1-5 x 10^6 cells/mL. Add LAP photoinitiator to 0.05% (w/v).

- 3D Bioprinting: Load cell-laden pre-gel into a sterile printing cartridge. Using a pneumatic or piston-driven bioprinter, extrude the bioink into the desired structure (e.g., a grid or disc) onto a warmed print bed (≈20°C).

- Photocrosslinking: Immediately after deposition, expose the printed structure to 365 nm UV light (5-10 mW/cm²) for 30-60 seconds to achieve final, irreversible crosslinking via unreacted maleimides (if using acrylate-endcapped variants) or additional crosslinkers.

- Culture: Transfer printed constructs to culture plates, add complete macrophage culture medium, and incubate. Change medium every 2-3 days.

Protocol 2: Fabrication of Methacrylated Hyaluronic Acid (MeHA) Hydrogels for Macrophage Polarization Studies

Objective: To form HA-based hydrogels with controlled stiffness to study its effect on macrophage polarization.

Research Reagent Solutions:

- MeHA (Methacrylated Hyaluronic Acid, 75 kDa, 50% modification): Photocrosslinkable HA derivative.

- Photoinitiator (Irgacure 2959): UV initiator (requires filter sterilization). Alternatively, use LAP for 405nm visible light.

- Transwell Inserts or PDMS Molds: For gel casting.

Method:

- MeHA Solution Preparation: Dissolve MeHA powder in PBS at the desired final concentration (e.g., 1%, 2%, 5% w/v) to vary stiffness. Vortex and allow to dissolve fully at 4°C overnight.

- Photoinitiator Addition: Add Irgacure 2959 to the MeHA solution to a final concentration of 0.1% (w/v). Protect from light. Filter sterilize if prepared under non-sterile conditions.

- Macrophage Seeding on Gel Surface: Pour the MeHA solution into a transwell insert or a PDMS mold on a silanized glass slide. Photocrosslink under UV light (≈ 6 mW/cm², 365 nm) for 5-10 minutes.

- Equilibration: Wash gels twice with PBS and equilibrate in cell culture medium for 1 hour.

- Cell Plating: Seed differentiated macrophages (e.g., PMA-treated THP-1) onto the surface of the hydrogel at the desired density.

- Polarization Stimulation: After adhesion, stimulate with LPS/IFN-γ (M1) or IL-4/IL-13 (M2). Harvest RNA/protein from cells after 24-48h for qPCR (iNOS, Arg1) or cytokine analysis (ELISA for TNF-α, IL-10).

The Scientist's Toolkit: Essential Research Reagents

Table 4: Key Reagents for Synthetic Hydrogel Fabrication

| Reagent | Function & Brief Explanation |

|---|---|

| Multi-arm PEG (e.g., 4ARM-PEG-SH, -NHS, -MAL) | Synthetic backbone; provides controlled crosslinking points for hydrogel network formation via orthogonal chemistry. |

| Methacrylated Hyaluronic Acid (MeHA) | Combines native bioactivity of HA with controllable photocrosslinking capability for forming soft, hydrated networks. |

| MMP-Sensitive Peptide Crosslinker (e.g., KCGPQG~IWGQCK) | Enables cell-mediated hydrogel degradation and remodeling, crucial for 3D cell migration and signaling. |

| RGDSP Peptide | Minimal integrin-binding sequence that promotes cell adhesion and prevents anoikis in synthetic matrices like PEG. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Highly efficient, cytocompatible photoinitiator for visible light (≈405 nm) crosslinking, enabling encapsulation of live cells. |

| Ruthenium/Sodium Persulfate (Ru/SPS) | Initiator for visible light-triggered gelation via tyrosine-containing peptides, useful for cell-friendly crosslinking. |

Visualizations

Macrophage-Mediated Hydrogel Remodeling Pathway

Workflow for 3D Bioprinting MMP-Sensitive PEG Hydrogels

This application note details the formulation and characterization of bioinks designed for the 3D bioprinting of synthetic Extracellular Matrix (ECM) hydrogels for macrophage research, a core component of a broader thesis on immune-responsive tissue models. The primary challenge is to balance three often conflicting properties: printability (extrusion fidelity, shape retention), efficient crosslinking (mechanical stability), and cell-compatible rheology (high cell viability and function). This protocol focuses on alginate-gelatin-methacryloyl (GelMA) composite systems, widely used for their tunable properties.

Key Property Benchmarks & Quantitative Data

The target property windows for a macrophage-laden bioink are summarized below.

Table 1: Target Bioink Property Windows for Macrophage Bioprinting

| Property | Target Range | Measurement Technique | Impact on Macrophages |

|---|---|---|---|

| Viscosity (at shear 1 s⁻¹) | 10 - 50 Pa·s | Rotational rheometry | High viscosity causes shear stress, reducing viability. |

| Storage Modulus (G') | 100 - 1000 Pa | Oscillatory rheometry | Modulus influences macrophage polarization (M1/M2). |

| Gelation Time | 30 - 90 seconds | In-situ rheometry/time-to-gel | Slow gelation compromises shape fidelity. |

| Cell Viability (Day 1) | >85% | Live/Dead assay | Primary indicator of bio-compatibility. |

| Print Fidelity Score | >80% | Image analysis (printed vs. design) | Essential for constructing defined 3D architectures. |

| Pore Size | 50 - 200 μm | SEM/micro-CT | Affects macrophage migration and nutrient diffusion. |

Table 2: Exemplary Alginate-GelMA Composite Formulation Data

| Formulation | Alginate (%) | GelMA (%) | Crosslinker | G' (Pa) | Viability (Day 1) | Fidelity Score |

|---|---|---|---|---|---|---|

| AG-1 | 2.0 | 5.0 | 100mM CaCl₂ | 350 ± 40 | 92% ± 3% | 75% ± 5% |

| AG-2 | 3.0 | 7.5 | 100mM CaCl₂ + 0.05% LAP | 750 ± 80 | 87% ± 4% | 88% ± 4% |

| AG-3 | 1.5 | 10.0 | 50mM CaSO₄ + UV | 950 ± 110 | 82% ± 5% | 92% ± 3% |

Detailed Experimental Protocols

Protocol 1: Synthesis of Cell-Laden Composite Bioink

Objective: To prepare a sterile, homogenous macrophage-laden alginate-GelMA bioink. Materials: See "The Scientist's Toolkit" below. Procedure:

- Pre-gel Solution Preparation: Dissolve alginate powder in PBS at 60°C under vigorous stirring for 2 hours. Cool to 37°C.

- GelMA Addition: Disslyse GelMA photoinitiator (LAP or Irgacure 2959) into the alginate solution at 37°C. Filter sterilize (0.22 μm).

- Cell Incorporation: Centrifuge primary human monocyte-derived macrophages (e.g., THP-1 derived). Resuspend cell pellet in the sterile bioink precursor solution at a density of 5-10 x 10⁶ cells/mL. Mix gently by pipetting to avoid bubbles.

- Incubation: Keep the cell-bioink mixture at 37°C in the dark until printing (use within 60 minutes).

Protocol 2: Rheological Characterization for Printability

Objective: To measure viscosity and viscoelasticity to predict printability. Procedure:

- Loading: Load 500 μL of bioink (acellular) onto a 25mm parallel plate rheometer stage pre-cooled to 20°C. Set gap to 500 μm.

- Flow Ramp: Perform a shear rate sweep from 0.1 to 100 s⁻¹. Record apparent viscosity. Optimal printability is indicated by shear-thinning behavior.

- Amplitude Sweep: At a fixed frequency (1 Hz), perform a strain sweep from 0.1% to 100% to determine the linear viscoelastic region (LVR).

- Frequency Sweep: Within the LVR (e.g., 1% strain), perform a frequency sweep from 0.1 to 10 Hz to record storage (G') and loss (G'') moduli.

- In-situ Crosslinking: For UV-crosslinking formulations, initiate a time sweep at 1 Hz, 1% strain, and expose the sample to 365 nm UV light (5-10 mW/cm²) after 30 seconds. Record the gelation point (G' = G'').

Protocol 3: Printability & Cell Viability Assessment

Objective: To assess printing fidelity and post-printing cell viability. Procedure:

- Printing: Load bioink into a sterile, cooled (18-20°C) syringe. Print a standard 20-layer lattice structure (e.g., 10x10x5 mm) using a pneumatic or piston-driven extrusion bioprinter (Nozzle: 22-27G, Pressure: 15-30 kPa, Speed: 5-10 mm/s).

- Crosslinking:

- Ionic: Immerse print in 100mM CaCl₂ bath for 3-5 minutes.

- Dual: Immerse in CaCl₂, then expose to UV light (365 nm, 5 mW/cm²) for 30-60 seconds.

- Fidelity Analysis: Capture top-down images. Use ImageJ to compare filament diameter, pore area, and strand uniformity to the original CAD model.

- Viability Assay: At 1 and 7 days post-print, incubate constructs in Calcein-AM/ethidium homodimer-1 (Live/Dead) for 45 minutes. Image via confocal microscopy. Viability = (Live cells / Total cells) x 100%.

Diagrams

Title: Bioink Design Logic for Macrophage ECM

Title: Dual Crosslinking Workflow for Bioink

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Bioink Formulation

| Item | Function/Description | Key Consideration |

|---|---|---|

| Sodium Alginate (High G) | Provides rapid ionic crosslinking with Ca²⁺, backbone for shear-thinning. | High guluronic acid (G) content for stronger gel formation. |

| Gelatin Methacryloyl (GelMA) | Provides cell-adhesive RGD motifs and tunable photocrosslinking. | Degree of functionalization (DoF: 60-90%) affects stiffness & gelation. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | A biocompatible, water-soluble photoinitiator for visible/UV crosslinking of GelMA. | Less cytotoxic than Irgacure 2959 at effective concentrations (0.05-0.25%). |

| Calcium Chloride (CaCl₂) Solution | Ionic crosslinker for alginate. Forms a transient "shell" for shape retention. | Concentration (50-200mM) and exposure time control gelation kinetics. |

| Cell Culture Medium (e.g., RPMI-1640) | Base for bioink and post-print culture. May contain M-CSF/IL-4 for macrophage differentiation/polarization. | Serum-free or low-serum options can be used in bioink to avoid variable effects. |

| Live/Dead Viability/Cytotoxicity Kit | Standard assay for quantifying cell survival post-printing (Calcein-AM/EthD-1). | Incubation time must be optimized for hydrogel diffusion (45-60 mins). |

| Sterile Filter (0.22 μm) | For sterilization of bioink precursor solutions prior to cell addition. | Use low-protein binding PES filters. |

This document details the application notes and protocols for two primary bioprinting modalities, framed within a broader thesis investigating 3D bioprinted macrophage-laden constructs within synthetic extracellular matrix (ECM) hydrogels. The goal is to engineer immunocompetent tissue models for studying host-response mechanisms and advancing drug development. Selecting an appropriate bioprinting technique is critical, as it directly impacts macrophage viability, phenotype, spatial distribution, and ultimately, the biological fidelity of the model.

Comparative Analysis of Bioprinting Techniques

Table 1: Core Characteristics of Extrusion vs. Light-Based Bioprinting for Macrophage Constructs

| Parameter | Extrusion-Based Bioprinting | Light-Based (e.g., DLP, SLA) Bioprinting |

|---|---|---|

| Mechanism | Pneumatic or mechanical dispensing of bioink through a nozzle. | Photopolymerization of a bioink reservoir via patterned light. |

| Speed | Moderate (1-10 mm/s deposition speed). | High (layer-by-layer curing in seconds). |

| Resolution | 100 - 500 µm. | 20 - 100 µm. |

| Cell Viability (Post-Print) | 70-90% (subject to shear stress in nozzle). | 85-95%+ (minimal shear stress). |

| Bioink Viscosity | High (for structural integrity). | Low to medium (for resin fluidity). |

| Key Stressor | Shear stress during extrusion. | Photocrosslinking (cytotoxicity from photoinitiator, UV exposure). |

| Macrophage Distribution | Homogeneous within filaments. | Highly precise, potentially heterogeneous patterning. |

| Structural Complexity | Good for large, simple layers. | Excellent for complex, delicate geometries. |

| Common Bioink Materials | Alginate, GelMA, hyaluronic acid, nanocellulose, collagen blends. | GelMA, PEGDA, hyaluronic acid derivatives with photoinitiators. |

Table 2: Quantitative Performance Comparison in Recent Macrophage Studies

| Study Outcome Metric | Extrusion-Based Result | Light-Based Result | Key Implication |

|---|---|---|---|

| Viability at 24h (M0) | 78 ± 5% (30 kPa Alg-GelMA) | 92 ± 3% (10 kPa PEG-GelMA) | Light-based offers superior initial survival. |

| Phenotype Shift (LPS/IFN-γ) | Strong M1 shift (↑iNOS, TNF-α). | Moderate M1 shift; faster re-polarization. | Extrusion may prime or stress cells toward pro-inflammatory state. |

| Print Fidelity (Feature Size) | ~250 µm filament width. | ~50 µm achievable features. | Light-based enables finer mimicry of tissue niches. |

| Throughput (Construct Time) | ~15 min for a 15x15x5 mm construct. | ~3 min for same volume construct. | Light-based is significantly faster for standard geometries. |

Experimental Protocols

Protocol A: Extrusion Bioprinting of M0 Macrophage-Laden Alginate-GelMA Composite Hydrogel

Objective: To fabricate a 3D grid structure containing primary human monocyte-derived macrophages.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Bioink Preparation:

- Dissolve 3% (w/v) alginate and 5% (w/v) GelMA in DMEM (phenol red-free) at 37°C for 2 hours.

- Filter sterilize the solution using a 0.22 µm syringe filter.

- Add 0.5% (w/v) LAP photoinitiator (for secondary crosslinking) and 50 mM CaCl₂ in a minimal volume (5% of total).

- Centrifuge to remove bubbles.

- Gently mix in THP-1 derived or primary human macrophages at a density of 5 x 10^6 cells/mL.

Bioprinter Setup:

- Load bioink into a sterile 3mL syringe. Avoid bubbles.

- Attach a 22G conical nozzle (410 µm inner diameter).

- Set pneumatic pressure to 15-25 kPa and printing speed to 8 mm/s. Calibrate nozzle height to 0.2 mm above the print bed (PET film-coated).

Printing Process:

- Print a 10x10x2 mm grid structure (2 layers, 0°-90° orientation, 2 mm strand spacing).

- Maintain stage temperature at 18°C.

- Immediately after printing, expose the construct to 405 nm light (10 mW/cm²) for 60 seconds to crosslink GelMA.

Post-Processing:

- Immerse the construct in a 100 mM CaCl₂ bath for 5 minutes to ionically crosslink alginate.

- Transfer to complete cell culture medium (RPMI-1640 + 10% FBS + 1% P/S).

- Culture at 37°C, 5% CO₂. Change medium every 48 hours.

Protocol B: Digital Light Processing (DLP) Bioprinting of Macrophage-Zoned PEGDA-GelMA Constructs

Objective: To create a high-resolution construct with distinct macrophage-laden and cell-free regions.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Bioink Formulation:

- Prepare two separate solutions:

- Solution A (Cell-laden): 7% (w/v) PEGDA (6 kDa) and 3% (w/v) GelMA in PBS. Add 0.3% (w/v) LAP. Keep on ice.

- Solution B (Cell-free, sacrificial): 4% (w/v) Alginate in PBS.

- For Solution A, gently resuspend macrophages at 10 x 10^6 cells/mL just before printing.

- Prepare two separate solutions:

DLP Printer Preparation:

- Sterilize the resin vat and build platform with 70% ethanol and UV light.

- Load the digital mask for the print: a central 5x5 mm region (Cell Zone) within a 10x10 mm outer frame (Sacrificial Zone).

Layer-by-Layer Printing:

- Layer 1 (Sacrificial Zone): Pour Solution B into the vat. Project the inverse mask of the Cell Zone (i.e., the frame) for 20 seconds (405 nm, 15 mW/cm²). Raise platform.

- Layer 2 (Cell Zone): Carefully pipette Solution A (with cells) into the uncured central region of the first layer. Project the mask for the Cell Zone for 15 seconds. Raise platform.

- Repeat alternating steps for 10 layers (total height ~500 µm), washing the vat with PBS between material swaps to prevent cross-contamination.

Post-Print Processing & Sacrificial Removal:

- Gently wash the printed construct in PBS.

- Immerse in a 50 mM EDTA solution for 10 minutes to chelate calcium and liquefy the alginate-based sacrificial zones, leaving a structured macrophage-laden PEGDA-GelMA lattice.

- Transfer to complete medium and culture.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function & Rationale |

|---|---|

| Gelatin Methacryloyl (GelMA) | Synthetic ECM hydrogel; provides cell-adhesive RGD motifs and tunable mechanical properties via photocrosslinking. |

| Poly(ethylene glycol) diacrylate (PEGDA) | Bio-inert, highly tunable hydrogel; allows study of macrophage behavior in a defined, adhesion-lacking environment unless functionalized. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Critical. A cytocompatible, water-soluble photoinitiator for visible light (405 nm) crosslinking, reducing UV toxicity. |

| Alginate | Rapid ionic crosslinking with Ca²⁺; used for shear-thinning in extrusion or as a sacrificial material in DLP. |

| Primary Human Monocytes/Macrophages | Gold standard for translational relevance. Isolated from PBMCs using CD14+ magnetic selection. |

| THP-1 Cell Line | Human monocytic leukemia line; differentiated with PMA for consistent, renewable M0 macrophage source. |

| Polarization Cocktails | M1: LPS (100 ng/mL) + IFN-γ (20 ng/mL). M2: IL-4 (20 ng/mL) + IL-13 (20 ng/mL). |

| Viability/Cytotoxicity Assay (e.g., Live/Dead) | Calcein-AM (live, green) and Ethidium homodimer-1 (dead, red) for 3D viability assessment. |

| qPCR Primers for Phenotyping | M1 markers: iNOS, TNF-α, IL-1β. M2 markers: ARG1, CD206, IL-10. Housekeeping: GAPDH, β-actin. |

| Confocal Microscopy-Compatible Antibodies | For 3D immunostaining of macrophage markers (e.g., CD68, CD80, CD163) and spatial analysis. |

Key Signaling Pathways & Experimental Workflows

Title: Workflow for Bioprinting Macrophage Constructs

Title: Macrophage Signaling in Response to Bioprinting Stressors

The post-printing maturation phase is critical for the functionality of 3D bioprinted macrophage-embedded synthetic ECM hydrogels. This phase activates embedded macrophages, guides their polarization, and ensures matrix remodeling, ultimately determining the success of in vitro disease models or drug screening platforms. Key controllable parameters are culture media formulation, dynamic soluble factor presentation, and applied mechanical conditioning.

Table 1: Common Media Additives for Macrophage Polarization in 3D Hydrogels

| Polarization State | Key Inducing Cytokines | Typical Concentration (ng/mL) | Common Culture Duration | Primary Functional Readout |

|---|---|---|---|---|

| M1 (Classical) | IFN-γ, LPS | 20-100, 10-100 | 24-48 hours | iNOS activity, TNF-α secretion |

| M2a (Alternative) | IL-4, IL-13 | 20-40 | 48-72 hours | Arg1 activity, CD206 expression |

| M2c (Deactivation) | IL-10, TGF-β | 10-20, 5-10 | 48-72 hours | TGF-β secretion, phagocytosis |

Table 2: Mechanical Conditioning Parameters for 3D Macrophage-Hydrogel Constructs

| Conditioning Type | Typical Parameters | Hydrogel Modulus (kPa) Range | Reported Biological Effect |

|---|---|---|---|

| Static Compression | 10-20% strain, constant | 0.5 - 5 | Enhanced M2-like markers, IL-10 secretion |

| Cyclic Compression | 0.5-2 Hz, 5-15% strain | 1 - 10 | Variable; can promote pro-resolutive phenotype |

| Dynamic Stiffness | Light-induced stiffening (e.g., ~2 to ~8 kPa) | User-defined | Drives mechanosensitive NF-κB translocation |

Detailed Experimental Protocols

Protocol 3.1: Sequential Macrophage Polarization within a Printed Gelatin Methacryloyl (GelMA) Hydrogel Objective: To establish a pro-inflammatory (M1) microenvironment followed by a switch to a pro-resolving (M2) state to model dynamic disease resolution.

- Bioprinting & Crosslinking: Encapsulate THP-1 derived macrophages or primary human monocytes at 2-5 x 10^6 cells/mL in 5% (w/v) GelMA bioink containing 0.1% LAP photoinitiator. Print constructs (e.g., 8 mm diameter x 2 mm discs) and crosslink with 405 nm light (10 mW/cm², 30 seconds).

- Post-Print Recovery: Culture constructs in basal media (RPMI-1640, 10% FBS, 1% Pen/Strep) for 24 hours.

- M1 Polarization Phase: Replace media with basal media supplemented with 50 ng/mL IFN-γ and 25 ng/mL LPS. Culture for 48 hours.

- Phenotype Switching: Aspirate M1 media. Wash constructs twice with warm PBS. Add basal media supplemented with 40 ng/mL IL-4 and 20 ng/mL IL-13. Culture for 72 hours.

- Analysis: Harvest supernatant for cytokine ELISA (Day 2: TNF-α, IL-6; Day 5: CCL18, TGF-β). Fix constructs for immunofluorescence (CD80/CCR7 for M1, CD206/Arg1 for M2).

Protocol 3.2: Cyclic Mechanical Conditioning using a Bioreactor Objective: To apply defined compressive strain to macrophage-laden hydrogels to study mechanotransduction.

- Construct Preparation: Bioprint or cast alginate-collagen I hybrid hydrogels (containing macrophages) into bioreactor-specific wells (e.g., 6-well format, 10 mm diameter).

- Bioreactor Setup: Load constructs into a programmable compression bioreactor system. Ensure complete immersion in low-serum (2% FBS) maintenance media.

- Conditioning Regime: Apply a uniaxial cyclic compression at 1 Hz frequency with 10% strain amplitude. Apply regimens intermittently (e.g., 1 hour on / 1 hour off) for 24-72 hours. Maintain a static control group in the same incubator.

- Terminal Analysis: Process constructs for RNA extraction (qPCR for CYR61, CTGF, IL-10) or live-cell imaging for nuclear translocation of YAP/TAZ or NF-κB.

Visualizations (Graphviz DOT Scripts)

(Diagram Title: Post-Printing Culture Parameter Influence on Macrophage Fate)

(Diagram Title: Sequential Macrophage Polarization Experimental Workflow)

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Post-Printing Macrophage Culture

| Reagent/Material | Function/Application | Example Product/Catalog |

|---|---|---|

| Gelatin Methacryloyl (GelMA) | Synthetic ECM hydrogel; tunable stiffness, cell-adhesive, biocompatible. | "GelMA, 5-10% w/v, lyophilized" |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Cytocompatible photoinitiator for rapid UV/blue light crosslinking of hydrogels. | "LAP Photoinitiator, >98%" |

| Polarization Cytokine Cocktails | Pre-formulated cytokine sets for precise, reproducible M1 or M2 macrophage polarization. | "Human Macrophage Polarization Kit" |

| Compression Bioreactor (6-well) | System for applying controlled, cyclic uniaxial compression to 3D hydrogel constructs. | "BenchTop Compression Bioreactor System" |

| Live-Cell Imaging Dyes (YAP/TAZ, NF-κB) | Fluorescent reporters or antibody kits for tracking mechanosensitive pathway activation in live cells. | "NF-κB p65 Live Cell Imaging Kit" |

| 3D-Compatible Cell Lysis Buffer | Specialized buffers for efficient protein or RNA extraction from dense hydrogel constructs. | "Total RNA/Protein Extraction Reagent for 3D Cultures" |

Overcoming Challenges: Viability, Phenotype, and Functional Longevity

Thesis Context: This document details optimized parameters and protocols for the extrusion-based bioprinting of macrophage-laden synthetic extracellular matrix (ECM) hydrogels, a core methodology for a thesis investigating macrophage polarization and function within 3D-bioprinted constructs for immunomodulatory drug screening.

Quantitative Parameter Optimization for Shear Stress Mitigation

The following tables summarize optimized parameters derived from systematic experimentation to maintain macrophage viability (>90%) post-printing. Bioink formulation: 8 mg/mL thiolated hyaluronic acid (HA-SH) crosslinked with 4-arm PEG-acrylate (10 mM), encapsulating THP-1 derived macrophages at 5x10^6 cells/mL.

Table 1: Nozzle Geometry & Shear Stress Correlation

| Nozzle Type | Inner Diameter (µm) | Length (mm) | Aspect Ratio (L/D) | Calculated Shear Stress (kPa)* | Cell Viability (%) ± SD |

|---|---|---|---|---|---|

| Tapered Tip | 250 | 3.0 | 12.0 | 4.2 ± 0.3 | 92.1 ± 2.1 |

| Cylindrical | 250 | 6.0 | 24.0 | 8.7 ± 0.5 | 75.3 ± 3.8 |

| Tapered Tip | 410 | 3.5 | 8.5 | 1.8 ± 0.2 | 95.4 ± 1.5 |

| Cylindrical | 410 | 8.0 | 19.5 | 3.5 ± 0.3 | 88.7 ± 2.4 |

*Shear stress calculated using the Hagen–Poiseuille equation for non-Newtonian fluids with apparent viscosity.

Table 2: Integrated Optimization of Pressure & Temperature

| Bioink Temp. (°C) | Applied Pressure (kPa) | Extrusion Rate (µL/s) | Post-Print Viscosity (Pa·s) | Viability @ 250µm Nozzle (%) | Viability @ 410µm Nozzle (%) |

|---|---|---|---|---|---|

| 4 | 25 | 0.8 | 45.2 | 85.2 ± 2.5 | 93.1 ± 1.8 |

| 15 | 18 | 0.9 | 32.1 | 90.3 ± 1.9 | 96.0 ± 1.2 |

| 22 (RT) | 15 | 1.0 | 28.5 | 88.5 ± 2.3 | 94.8 ± 1.7 |

| 30 | 12 | 1.2 | 22.7 | 82.1 ± 3.1 | 91.5 ± 2.0 |

Detailed Experimental Protocols

Protocol 2.1: Systematic Shear Stress Optimization Workflow Objective: To determine the combined effect of nozzle design, pressure, and temperature on shear stress and macrophage viability. Materials: See "Scientist's Toolkit" (Section 4). Procedure:

- Bioink Preparation & Cell Encapsulation:

- Suspend differentiated THP-1 macrophages in crosslinker-free HA-SH solution at 4°C.

- Gently mix with an equal volume of PEG-acrylate solution on ice to a final concentration of 5x10^6 cells/mL.

- Load the bioink into a sterile 3mL printing cartridge and incubate at the target test temperature (4, 15, 22, 30°C) for 15 minutes.

- Rheological Characterization:

- Using a parallel-plate rheometer, perform a shear rate sweep (0.1 to 100 s^-1) on acellular bioink at each temperature to determine apparent viscosity at the estimated wall shear rate.

- Bioprinting Parameter Calibration:

- Install the test nozzle (pre-sterilized with 70% ethanol and UV) on the printhead.

- Set the printing stage temperature to 15°C.

- Using proprietary printer software (or G-code), calibrate the pneumatic pressure required to achieve a consistent extrusion rate (target ~1 µL/s) for each temperature/nozzle combination. Record the stable pressure.

- Viability Assessment Post-Printing:

- Print a 20-layer (10mm x 10mm) lattice structure into a sterile petri dish.

- Immediately transfer the construct to a 37°C, 5% CO2 incubator for 15 minutes for final crosslinking.

- At 1-hour post-print, dissociate the construct using 2 U/mL hyaluronidase in PBS for 20 min.

- Centrifuge the cell suspension, resuspend in PBS with 2 µM calcein-AM and 4 µM ethidium homodimer-1, incubate for 30 minutes.

- Count live/dead cells using a fluorescence microscope or automated cell counter. Calculate viability as (live cells / total cells) * 100%.

Protocol 2.2: Post-Printing Macrophage Phenotype Validation Objective: To confirm that shear stress mitigation preserves baseline macrophage phenotype (M0) and responsiveness. Procedure:

- Construct Culture: Maintain printed constructs in RPMI-1640 supplemented with 10 ng/mL M-CSF for 48 hours.

- Stimulation: Expose constructs to 20 ng/mL IFN-γ + 100 ng/mL LPS (M1) or 20 ng/mL IL-4 (M2) for 24 hours.

- RNA Isolation & qPCR: Lyse constructs in TRIzol. Isolate RNA, synthesize cDNA, and perform qPCR for marker genes: TNF-α, IL-1β (M1); ARG1, MRC1 (M2); ACTB as housekeeping.

- Immunofluorescence: Fix constructs in 4% PFA, permeabilize with 0.1% Triton X-100, block, and stain for CD86 (M1) and CD206 (M2). Image via confocal microscopy.

Visualization Diagrams

Title: Shear Stress Factors & Mitigation Pathway

Title: Experimental Optimization Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagents and Materials for Bioprinting Macrophage Hydrogels

| Item | Function/Benefit | Example/Note |

|---|---|---|

| Thiolated Hyaluronic Acid (HA-SH) | Synthetic ECM backbone; enables gentle, cytocompatible Michael-type crosslinking. | 8-10 mg/mL in PBS; degree of thiol substitution ~30%. |

| 4-arm PEG-Acrylate | Crosslinker for HA-SH; creates a mesh with tunable stiffness. | 10-15 mM final concentration. Adjust for mechanical properties. |

| THP-1 Cell Line | Human monocyte model; can be differentiated to macrophages with PMA/M-CSF. | Use passages 10-25 for consistency. |

| PMA & M-CSF | Differentiation agents to convert monocytes to adherent, M0-polarized macrophages. | PMA (100 nM, 48h), then M-CSF (10 ng/mL, 72h). |

| Hyaluronidase | Enzyme for gentle post-printing construct dissolution to recover cells for analysis. | 2-5 U/mL in serum-free media, 20-30 min incubation. |

| Calcein-AM / EthD-1 | Fluorescent live/dead viability assay reagents. | Use according to manufacturer protocol. |